The Machinery Regulation (EU) 2023/1230, published in the Official Journal on 29 June 2023, is set to mark a turning point in the European regulatory landscape for industrial automation, becoming the new benchmark for machinery safety. As full application approaches in 2027, the industry is preparing to adapt to clearer rules, better suited to today’s manufacturing environment and capable of governing emerging technologies such as connected systems and artificial intelligence.

What the New Machinery Regulation 2023/1230 Introduces

The new regulation was designed to overcome the limitations of the existing Machinery Directive in an industrial context that has radically changed since the early 2000s. The shift from a directive to a regulation is key, as it introduces rules that apply directly across the entire Union, without country-by-country interpretative differences. This alone represents a benefit for manufacturers and developers operating at European level.

The text deeply redefines key terms such as machine, safety component, safety function and substantial modification. This update is essential in a context where the boundary between hardware and software has become increasingly blurred, with digital features continuously influencing and modifying device behaviour. Modern systems communicate, collect data, adapt to their operating environment and, in some cases, update their functionalities autonomously. The Regulation acknowledges these developments and introduces targeted requirements to manage them effectively and safely.

Its underlying logic is twofold: on the one hand, ensuring a high level of safety for end users; on the other, facilitating the free movement of machinery through a harmonised framework that reduces past ambiguities. The goal is to provide companies with a clear regulatory tool capable of addressing both established technologies and emerging ones—from robotic applications to connected systems, up to software that directly affects safety functions.

Key Points of the Machinery Regulation 2023/1230 for Industry and Industrial Automation

The new Regulation introduces significant changes that directly impact how companies design, document, and manage automated systems. Among the main points of interest for manufacturers and operators are:

- Digital technical documentation: Instructions and manuals can be provided in digital format, as long as they remain accessible throughout the system’s lifecycle and are easy to consult and print on request.

- Software management: Updates affecting functions or safety must be carefully assessed. System behaviour is no longer static and must be monitored and controlled throughout its evolution.

- High-risk machinery classification: Certain categories require mandatory involvement of conformity assessment bodies, increasing oversight over critical functions.

- Roles and responsibilities of economic operators: Manufacturers, distributors and importers must share responsibilities along the entire supply chain, ensuring device traceability and compliance.

- Autonomous and connected machinery: Robotic systems and autonomous mobile vehicles must include dedicated supervisory and safety functions to ensure operator control and protection.

- Market surveillance and penalties: Member States are required to verify machinery compliance, imposing corrective actions when necessary and reinforcing product safety and reliability across the market.

These changes not only raise safety standards but also give companies the opportunity to reorganise processes, improve digital risk management and enhance the value of technologies already present in their production lines.

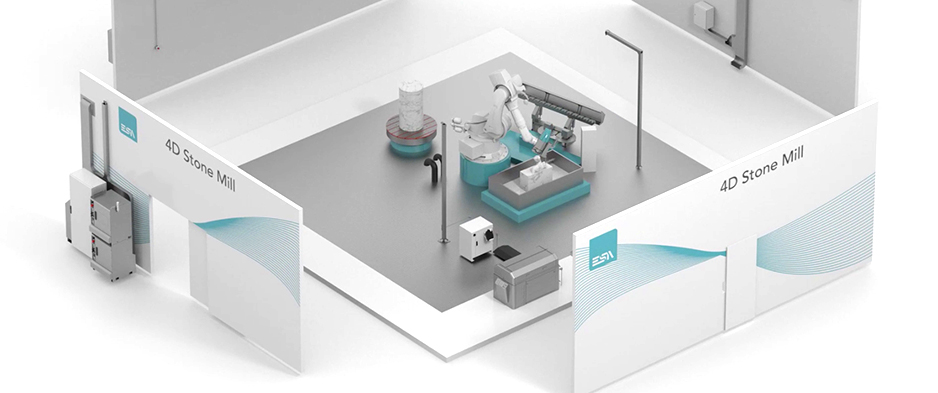

ESA and the Machinery Regulation: Solutions Ready for the New Requirements

The new Machinery Regulation requires increasing focus from manufacturers on functional safety, software management and digital lifecycle control. In this context, ESA Automation & Robotics develops solutions designed to comply with the new rules, integrating innovative safety features. The goal is to offer technologies that help meet regulatory requirements while improving reliability and operational continuity.

Cybersecurity also plays a central role. For this reason, ESA Automation & Robotics develops solutions to protect infrastructures and data, limit risks of unauthorised access and ensure operational continuity. The integration of these features enables companies adopting our technologies to approach the new regulatory framework with tools already designed to support the required standards.