In a smart factory, increasing productivity and minimizing machine downtime is a tangible necessity. Robotics As A Service (RaaS) gives companies the ability to access robots and automated systems as a service, without the need for significant investments in machines and software. This model allows production to scale flexibly, adopt new technologies quickly, and adapt to fluctuations in demand without compromising efficiency or operational continuity.

RaaS: Flexible Robotics as a Service

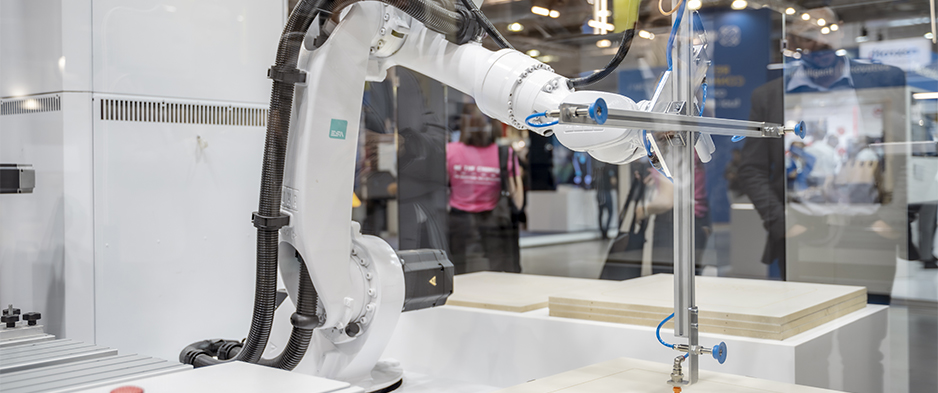

RaaS moves robotics beyond the traditional concept of fixed investment, turning it into an accessible service. Companies connect to platforms managed by providers, who supply robots, control software, and maintenance services, without requiring the client to handle the more complex technical aspects. Payments are based on measurable parameters such as usage hours, production cycles, or performance according to specific indicators. This approach keeps flexibility high and reduces the risk of investing in machines that can quickly become obsolete.

Beyond the economic aspect, RaaS simplifies operational management. Providers ensure continuous updates and remote monitoring, allowing maintenance interventions to be anticipated before faults occur. Companies can therefore focus on production activities without worrying about complex installations or specialized technical skills. This model also encourages experimentation. Companies can quickly test new robots or configurations without constraints, adapting automation to production changes and market developments.

How RaaS Redefines Industrial Production

In the industrial sector, the RaaS approach brings greater agility to production. Companies experiencing seasonal peaks or demand variability can increase the number of robots during high-load periods and scale down when necessary, avoiding high fixed costs. Operations running continuous processes benefit from guaranteed maintenance and constant updates, ensuring efficiency and uninterrupted continuity.

Integration goes beyond the physical presence of robots; it also involves managing data and processes. Thanks to the Internet of Things, sensors and software enable real-time performance monitoring, fault prediction, and optimization of every production stage. This reduces waste, enhances safety, and frees human resources for higher-value activities. In complex environments, where production lines must adapt to varying batches or product types, new configurations can be tested quickly and safely, with implementation times far shorter than traditional robotics.

For small and medium-sized enterprises, in particular, this model represents a tangible opportunity to enter automation without large upfront investments. It allows testing processes, evaluating returns, and making future strategy decisions based on concrete data. In an era where flexibility and speed are essential, on-demand robotics transforms industrial automation into a dynamic, adaptable journey tailored to the real needs of the business.