The Industry 4.0 has shifted the focus on the importance of automated and interconnected production.

More accessibility, efficiency and ability to exchange big volume of data among themselves: these are, in fact, the most important characteristics to look for in production machines and technologies, both to be competitive and to keep up with the new industrial principles.

Industry 4.0 and the IoT principles

Like every industrial revolution, the Industry 4.0 brings some key turning points in the way we “do industry”.

- Smart production.

- Digitalization of the supply chain.

- Digital business products, services and models.

- Information access and circulation as a competitive factor.

In short, everything seems to be turning around a more efficient, more accessible and more digital ideal of industry.

In order to fully achieve this reality, however, we need the right conditions. Specifically, companies need technology support that enables them to put in place automated and interconnected production.

This very concept brings us back to the principle of the Internet of Things. That is, the need for machines and software to communicate and exchange data independently among each other, in order to promote the circulation of ever larger volumes of information.

And since the IoT is a fundamental principle for the Industry 4.0, connectivity and automation are indispensable values.

ESA Automation and its solutions for the Industry 4.0

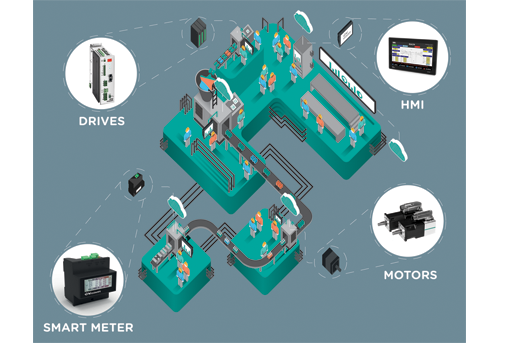

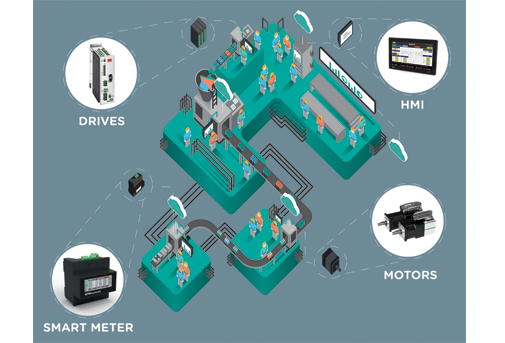

The principles of Industry 4.0 and IoT are the foundations on which ESA Automation has created its latest solutions for industrial automation.

Starting with its software products, which promote automated and interconnected production in any industrial sector.

Like Everyware, the remote assistance platform that allows you to intervene from anywhere, reducing maintenance costs and time, on top of cutting downtimes. In other words, a very high level of connectivity, perfect in today’s industrial context.

Find out more about the ESA Automation software solutions for company digitalization

The ESA Automation Cloud service is one of the latest innovations. Another important step towards an IoT future.

In fact, this platform makes it possible to gain immediate access to plant data, promoting the integrated operation of the systems connected to the facility. In addition, it guarantees up to 25% more productivity.

Finally, the Esaware IPCs also meet the needs of the Industry 4.0.

In addition to providing a great visualization and control application in any production plant, they offer many 4.0-friendly features. For example:

- Multiple Ethernet connectivity to the network, 2 or 4 standard LANs.

- The use of Fanless and low consumption CPUs dedicated to industrial IoT.

- The new DDR3L / DDR4 SDRAM memories.

But that’s not all. ESA Automation offers a wide range of solutions for industrial automation and energy management that are geared towards a more and more automated and interconnected production

Visit our product page to find out more.