Physical AI: When Artificial Intelligence Moves into the Factory Floor

Within the Industry 5.0 framework, artificial intelligence is becoming increasingly hands-on. It is no longer limited to data analysis or decision support: AI is now embedded directly into production processes. Machine vision systems inspect quality in real time, robots adjust to part variability, and smart platforms can detect early signs of instability or unplanned downtime. This is where the concept of Physical AI comes into play, operating inside the physical reality of the factory.

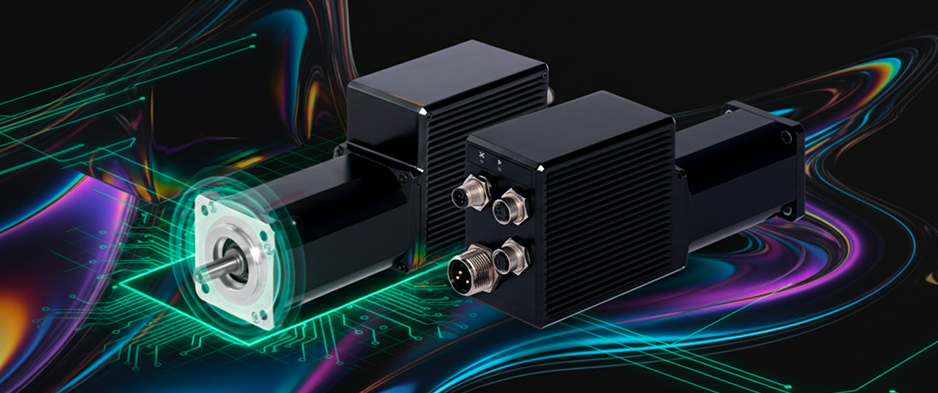

EWDB: Compact and Efficient Servo Drive

The EWDB integrated servo drive from Esa Automation & Robotics is the perfect solution to meet the demands of modern automation. Designed for compact, modular, and energy-efficient machines, the EWDB combines motor and drive into a single unit, optimizing space and simplifying wiring. Ideal for machine builders and system integrators, it’s the smart choice to boost productivity, efficiency, and flexibility.

AI Act: Italy Is the First EU Country to Implement the Regulation

With the approval of Law No. 132 of 2025, Italy becomes the first country to fully align with the AI Act, the EU’s landmark regulation setting common rules for the use of artificial intelligence. The new national law provides businesses with a clear regulatory framework designed to balance innovation and safety. It marks a major regulatory milestone for the responsible management of AI in Italy, positioning the country as a reference point within the European regulatory landscape.

Industrial Robotics 2026: toward more predictive, collaborative, and autonomous systems

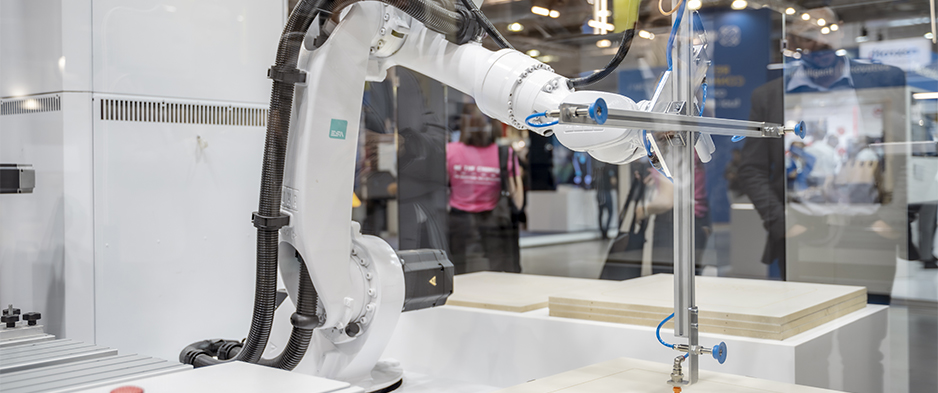

Industrial robotics in 2026 is not just an automation lever, but a true driver of operational intelligence. Robots are increasingly able to anticipate what is coming, collaborate with people and adapt to production environments in real time. Powered by AI, advanced sensing and deep digital integration, this evolution is reshaping how manufacturing processes are designed and how factories operate.

Industrial Automation: Outlook for 2026

After two challenging years marked by slowdowns, geopolitical tensions, and more cautious investment approaches, industrial automation is ready for a fresh start. While 2026 is unlikely to spark a new investment boom, it promises a period of more deliberate and balanced growth. Companies will focus on technologies that boost efficiency without compromising flexibility or sustainability, positioning themselves to navigate a complex and evolving market.

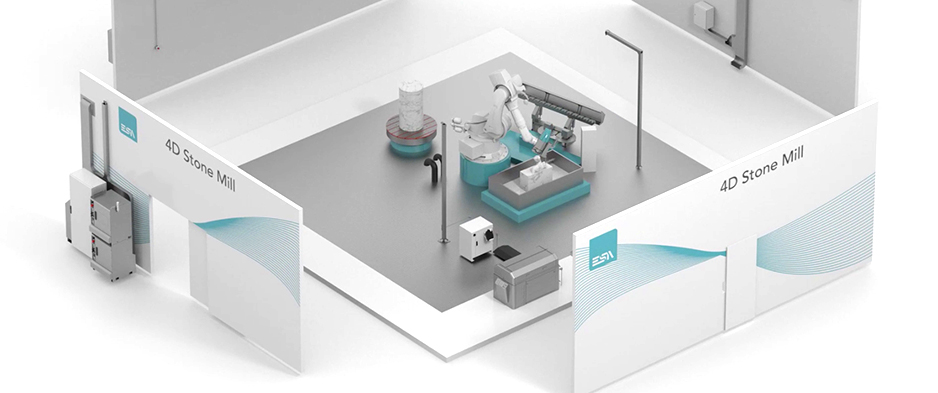

ESA Automation & Robotics Sustainability Report 2025

ESA Automation & Robotics presents its 2025 Sustainability Report. This document illustrates how technology, innovation, and environmental responsibility can be integrated into a concrete path toward sustainable development. The goal is to provide a clear view of our contribution to improving production processes, reducing environmental impact, and creating shared value for employees, customers, and communities.

Prescriptive Maintenance: The Next Step Beyond Predictive Maintenance

Smart production lines generate increasing amounts of data, creating new opportunities to turn information into operational advantage. In this context, prescriptive maintenance is becoming a strategic approach. It does not only indicate when a machine might fail but also recommends the most effective actions to prevent downtime. This shift transforms maintenance into a practical tool for improving efficiency, production continuity, and plant resilience.

New Machinery Regulation 2023/1230: an update ahead of its entry into force

The Machinery Regulation (EU) 2023/1230, published in the Official Journal on 29 June 2023, is set to mark a turning point in the European regulatory landscape for industrial automation, becoming the new benchmark for machinery safety. As full application approaches in 2027, the industry is preparing to adapt to clearer rules, better suited to today’s manufacturing environment and capable of governing emerging technologies such as connected systems and artificial intelligence.

Machine Vision: how the world of robotics is evolving

Robots today are no longer limited to following predefined instructions. Thanks to machine vision, they can interpret their surroundings and react accordingly. From warehouses to production lines, this technology is becoming a decisive driver of modern robotics, making processes faster, more accurate, and far more adaptable.

Robotics as a Service (RaaS): how it works and how it integrates in the industrial sector

In a smart factory, increasing productivity and minimizing machine downtime is a tangible necessity. Robotics As A Service (RaaS) gives companies the ability to access robots and automated systems as a service, without the need for significant investments in machines and software.